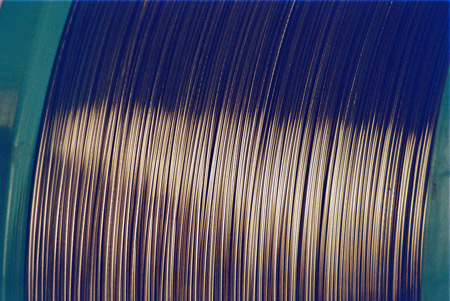

Nickel Plated Wires

Lead-in-wires are produced by welding three wires - namely; the Inner Lead (which supports the filament), Press or Seal (which provides the glass-to-metal seal), and the Outer Lead (which is directly connected to the power source).

For most the 3-part and 2-part lamps, the inner lead material is mostly made of Nickel Plated Steel (NPS) or Nickel Plated Bronze (NPCuSn) or Nickel Plated Copper (NPC) wire. The NPS wire is also used as a support wire in Standard Fluorescent Lamps (FTL).

Gem manufacturers all the above three materials in its "state-of-the-art" facility for in-house consumption and exports worldwide. The wires are bright, smooth and highly suitable to make lead-in-wires on automatic, high-speed machines.

These wires confirm to the relevant customer specifications or international standards, as per requirements. The wires are available in various DIN Spools from DIN 80 to DIN 355 depending on diameter of the wire and the customer's requirement.

Broad Properties and Specifications

The following table gives properties of these wires in general. Please contact us for more detailed specification of these wires.

| Description of wire | Sizes Available (dia in mm) Tolerance on dia: ±0.01 |

Plating Thickness (in micron) |

Tensile Strength (in N/mm2) |

Elongation 200 mm (in %age) |

|

|---|---|---|---|---|---|

| Nickel Plated Steel Wire (NPS) | 0.4 to 2.5 | 1.5 to 5.0 | Soft Quarter Hard Half Hard Hard |

300-400 450-550 550-700 800-1050 |

20 Min 10 Min 5 Max 5 Max |

| Nickel Plated Copper Wire (NPC) | 0.4 to 2.5 | 1.5 to 5.0 | Soft Hard |

210-300 400-500 |

25 Min 5 Max |

| Nickel Plated Bronze Wire (NPB) | 0.4 to 1.0 | 1.5 to 5.0 | Soft Hard |

250-350 450-500 |

20 Min 5 Max |

Nickel Plated Wires to other properties and specifications can also be supplied to customer specifications.

For other Lead-in-Wire raw materials (Nickel, Nickel-Copper alloy wire, Dumet wire, etc.) and lamp components, please visit : JLC Electromet for nickel alloys.