Quality

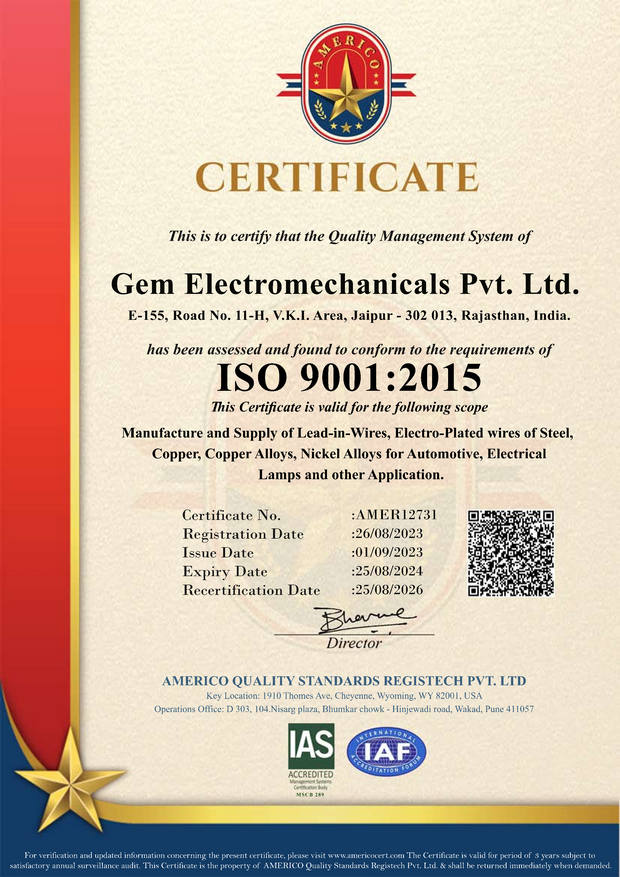

GEM is an ISO 9001:2015 certified company. For ensuring the highest quality of our products, we have put in practice stringent Quality Management Systems (QMS). Besides process control, quality plans are used for testing at incoming, in-process and finished material stages using sophisticated equipment. All critical process parameters are controlled using SPC tools and all processes are set using FEMA to ensure high quality of products.

The finished lead-in-wires are made with focus on the following critical dimensions within customer specified limits:

- Weld Strength and Weld Eccentricity

- Dimensions – diameters and lengths of individual leads and overall length

- Weld Diameter

- Straightness and Good finish

GEM maintains continuous in-process inspection and final inspection ensures the highest quality level. We have fully equipped in-house laboratories for testing chemical, metallurgical and electro-magnetic properties of the materials. These are supported by an experienced team of dedicated engineers.

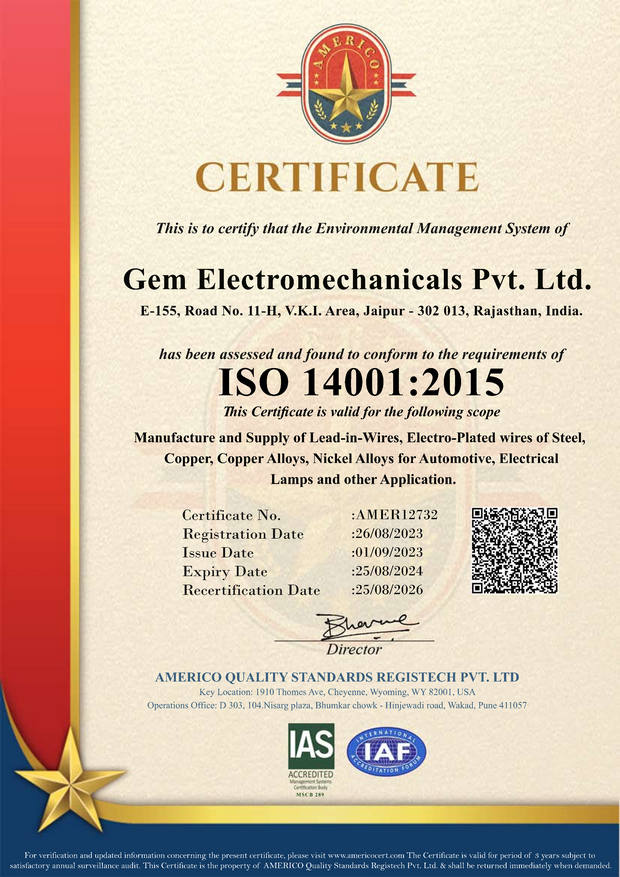

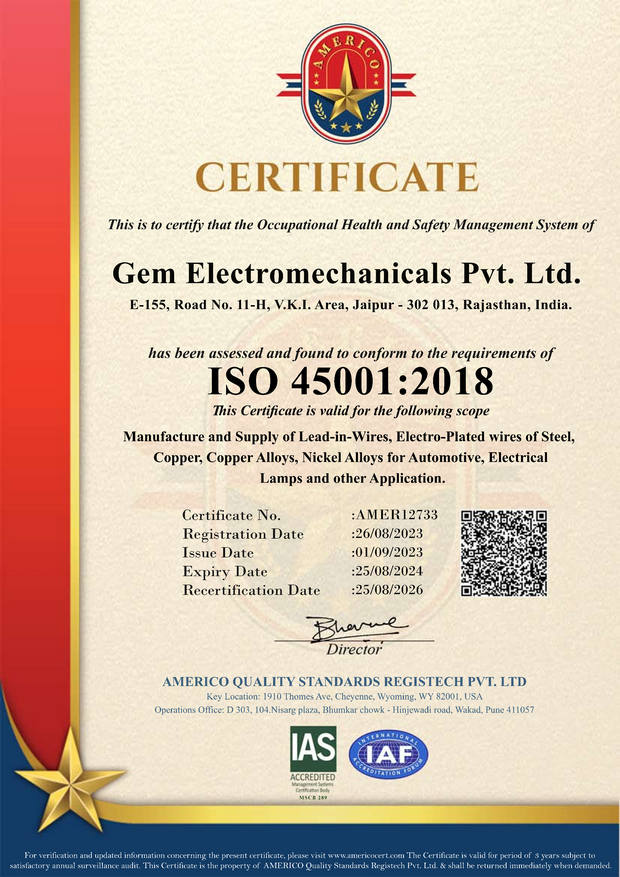

GEM Electro is committed to Electronic Industry Code of Conduct. Being ISO 14001:2015 and OHSAS 45001:2018 certified company, GEM Electro is committed to the Company Policy of:

- Clean, Safe & Healthy working conditions in supply chain for all its employees and also with its customers and suppliers

- Workers are treated with dignity

- Manufacturing processes are environmentally responsible

- Uphold highest standards of integrity - prohibit all forms of corruption

- Respect Intellectual Property Rights within the company , with customers & with suppliers